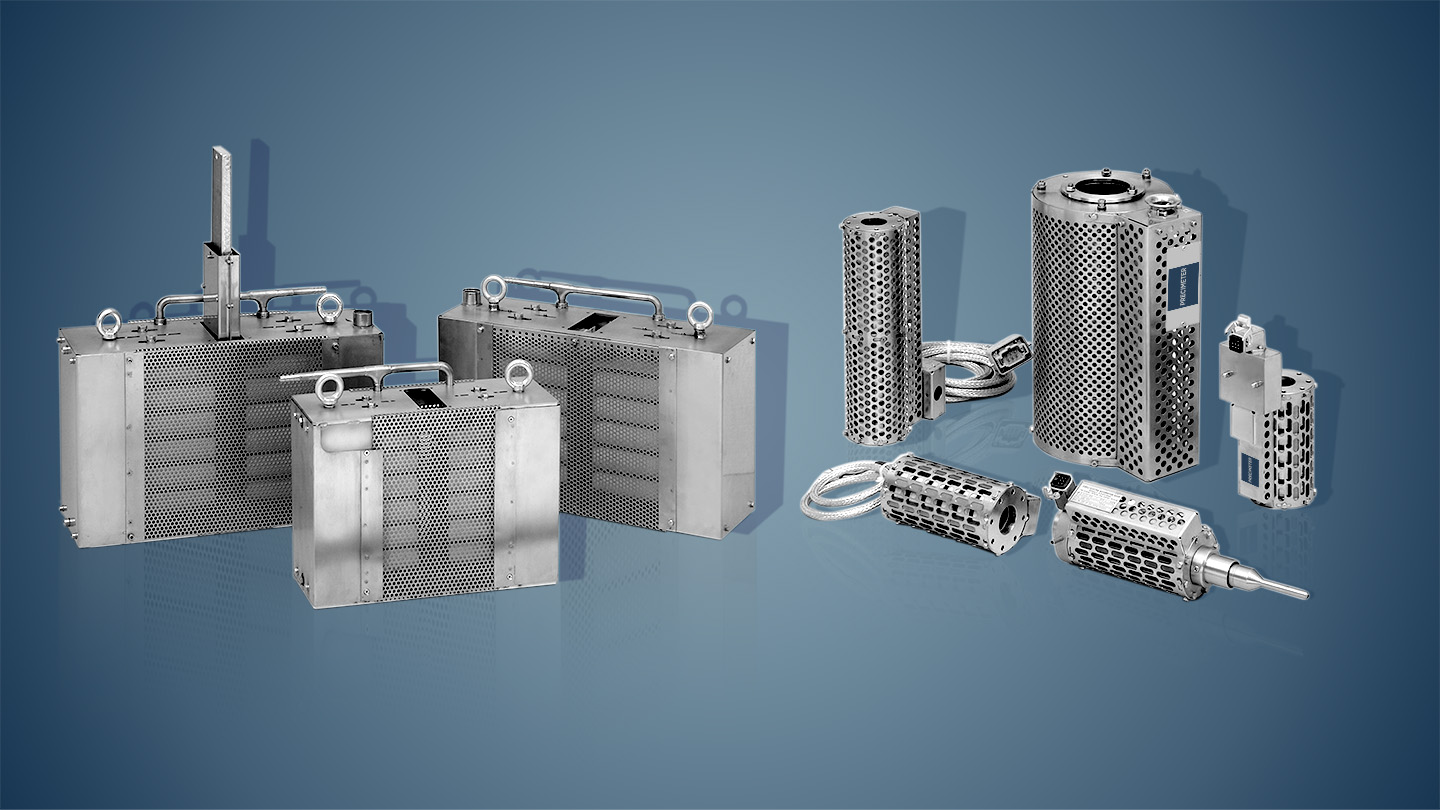

Precimeter manufacture a variety of molten metal level and flow control actuators. Our actuators respond quick and accurate to changes in command and have long, reliable life spans.

Specifically designed for molten metal level measurement in closed or open systems.

Specifically designed for molten metal level measurement in launders, furnaces, crucibles, moulds and more.