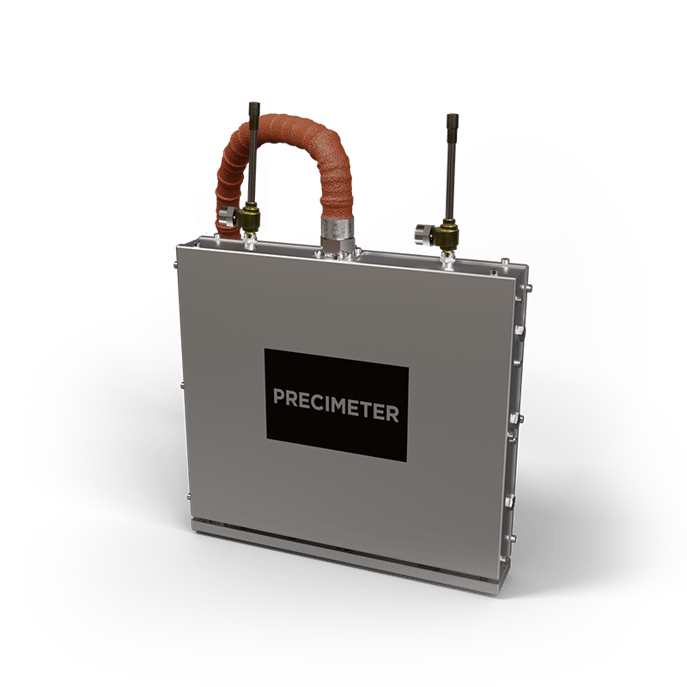

ProV

Specially designed to measure on molten metal surfaces above 1200˚C. Works on all High temperature alloys.

Violet laser

Designed for ferrous metals with a violet laser

Accurate measurement

Laser camera triangulation provides precise readings

Stable performance

Advanced technology enables balanced readings in any condition

Control in every step

Stable readings in reflective and harsh conditions

Stable readings on reflective surfaces

The Laser Camera Sensor model ProV from Precimeter combines high performance laser triangulation with the necessary control functions to maintain an accurate molten metal level measurement. The digital camera technology in the Precimeter sensors results in very high performance and resolution.

The advanced technology enables stable readings even when the molten metal material reflectivity changes dramatically and/or in harsh conditions with heavy steam and smoke environment.

Advantages with ProV Laser Camera Sensor

| Power Requirement | 24 VDC < 1 A |

|---|---|

| Level Output | 4–20 mA |

| Internal Temp Output | 4–20 mA (0–100°C, 32–212°F) |

| Digital Input | Light source on/off |

| Digital Output | Sensor status |

| Resolution | ±0.07 mm |

| Ethernet Protocol | Optional (Profinet, Ethernet IP or Modbus TCP) |

| Interface | Precimeter tool (PC software) |

| Sampling Rate | 50 Hz |

| Laser Power | < 1 mW (Laser class 2) / < 5 mW (Laser class 3R) |

| Cooling | Compressed air (3/8” connection) |

Sensor models

| Sensor Model | Clearance Distance | Measurement Distance |

|---|---|---|

| Sensor Model ProV CD1150R400 | Clearance Distance 1150 mm (45.3”) | Measurement Distance 400 mm (15.8”) |

| Sensor Model ProV CD2350R3000 | Clearance Distance 2350 mm (92.5”) | Measurement Distance 3000 mm (118.1”) |